Horizontal Directional Drilling (HDD)

Horizontal Directional Drilling (HDD) is a trenchless method of installing underground pipelines, cable systems and service conduit underground along a predetermined path without causing disruption to ground services

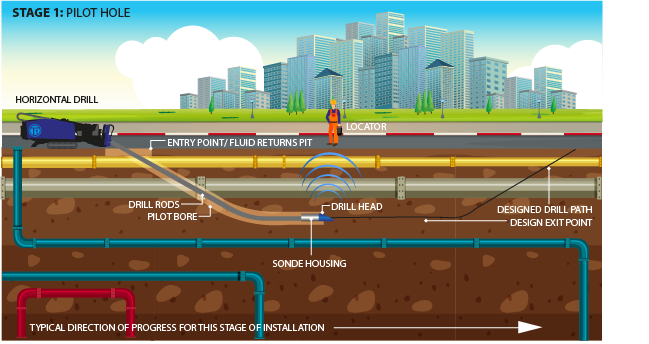

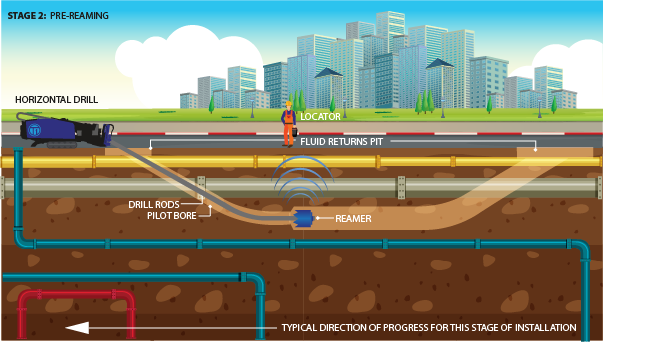

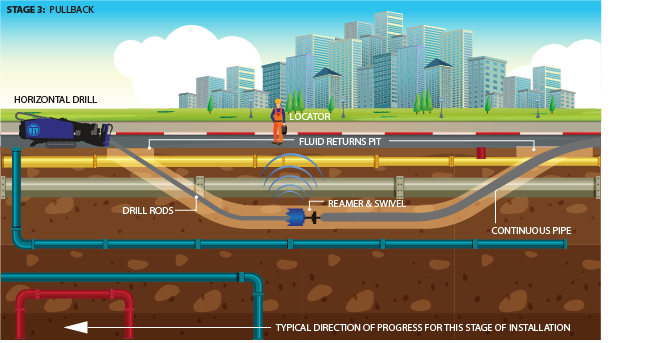

Directional Drilling is a 3 Stage process:

Once the drilling machine is set up a small hole is drilled following a predetermined drill plan. The drill head sends a signal to the locating unit via a ‘Sonde’. The sonde transfers 3 pieces of information to the locating equipment – the pitch, the roll and the depth of the drill head. This information is used to determine the current location of the drill head and is also used to steer the drill head to the next target point.

Once the pilot hole is successfully completed a ‘Reamer’ is attached to the front of the drill string and pulled back to the drilling rig to enlarge the pilot hole. The final size reamed hole is in general 1.25 to 1.5 times the diameter of the pipe to be installed.

Depending on the size of the pipe this may include 2 or 3 passes to get it to the desired bored size.

The final stage involves pulling the pressure pipe through the enlarged pilot hole. To do this the pipe is attached to the drill rod and pulled into the ground in a continuous operation. A swivel is utillised between the reamer and pipe being installed to minimize torsion transmitted to the pressure pipe as it is being pulled through the enlarged pilot hole into its final position

Business Hours

-

Mon - Thurs: 7:00am - 7:00pm

-

Friday: 7:00am - 4:00pm

Locations

-

LOWER HUTT:69 Eastern Hutt Rd, Taita

-

PORIRUA:4 Mohuia Cres, Elsdon